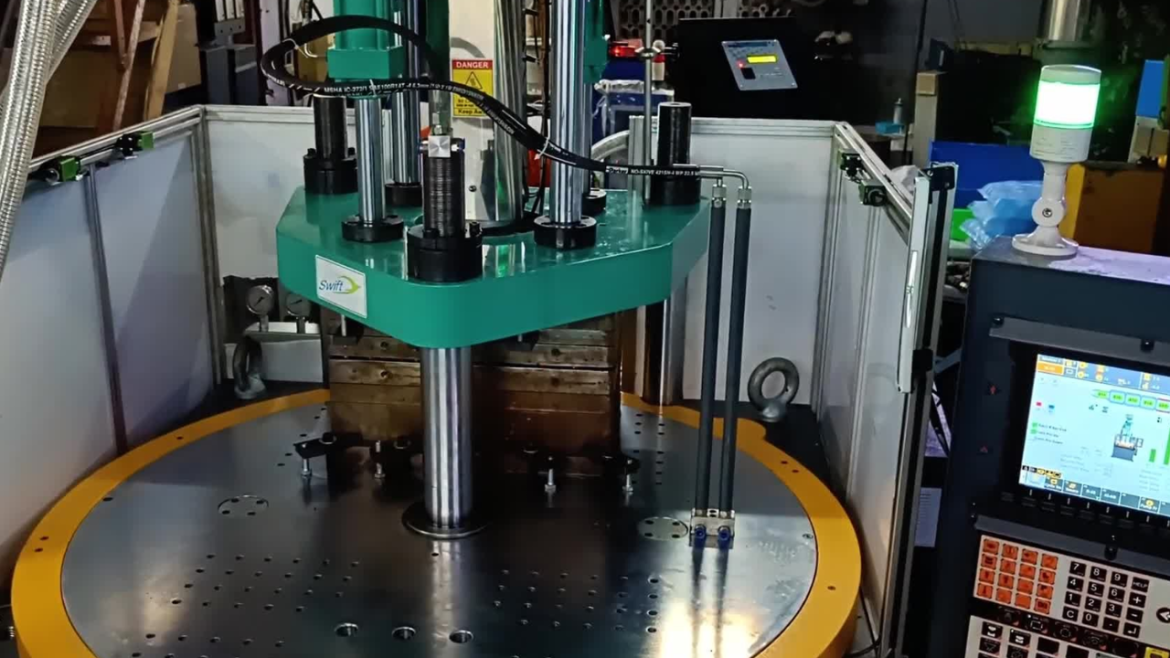

The minhui rotary table injection machine gives progressive capabilities and advanced generation to satisfy the demands of present-day manufacturing. With its precision-engineered rotary table design, this machine permits efficient manufacturing of complicated molded parts with high accuracy and repeatability.

The machine’s robust creation and dependable performance make it suitable for a wide variety of packages, from automotive and electronics to clinical devices and customer items. Equipped with complete safety functions and user-pleasant controls, the Minhui rotary table injection device guarantees operator safety and simplicity of operation.

Considerable Safety Measures

Working a rotary desk injection system requires strict adherence to safety protocols to shield operators, prevent injuries, and make sure of secure working surroundings. Here are numerous safety measures that must be implemented when working a rotary table injection system:

System Guarding

Proper device guarding is vital to save your operators from having access to hazardous regions for the duration of the operation. Interlocking protection doorways set up interlocking safety doors across the gadget to save you entry to the mildew region and shifting elements when the gadget is in operation. Erect perimeter fencing across the machine to create a physical barrier that restricts admission to the operating location. Make sure that the fencing is tall enough to prevent inadvertent access and is ready to get admission to gates managed by way of interlocks.

Emergency Stop Devices

Emergency stop devices offer a quick and easy manner to halt device operations in case of an emergency. Easily on hand Buttons region emergency prevent buttons or switches at multiple locations across the machine, which includes near the operator station and at key get entry to points. Ensure that operators can reach them speedily in case of an emergency. Label emergencies prevent controls with different shades and emblems to make them without problems identifiable to operators.

Lockout/Tagout Strategies

Lockout/tagout (LOTO) techniques are crucial for stopping accidental startup or movement of the gadget for the duration of maintenance or servicing. Develop and implement LOTO approaches to isolate and de-energize all electricity sources, consisting of electrical, hydraulic, and pneumatic systems, earlier than performing renovation duties. Use lockout gadgets, inclusive of padlocks and lockout hasps, to secure power isolation devices and prevent them from being operated inadvertently. Attach tags to truly suggest the reason for the lockout and the responsible personnel.

Non-Public Shielding Device (PPE)

Require operators to wear suitable private defensive equipment (PPE) to minimize the risk of damage in the course of system operation. Defend operators’ eyes from flying particles, splashes, and other dangers generated throughout the molding process. Listening to protection provides earplugs or earmuffs to guard against excessive noise levels produced by using the system and auxiliary devices.

Safe Work Practices

Promote and enforce secure work practices to decrease the risk of injuries and accidents throughout device operation. Schooling provides comprehensive education to all operators on safe system operation, emergency processes, and hazard popularity. Make sure that new hires receive the right training earlier than working the device independently. Take away any boundaries or particles that could obstruct admission to emergency exits or safety systems.

Ordinary Inspection

Regular inspection and maintenance of the machine are crucial to perceive and cope with ability protection hazards and mechanical problems. Scheduled Inspections set up a regular timetable for analyzing the device and coping with any troubles directly. Perform preventive maintenance responsibilities, inclusive of lubrication, alignment checks, and component substitutes, in keeping with the producer’s pointers. Keep precise information on all renovation sports for documentation and duty.

Bottom Line

With the aid of enforcing those protection measures whilst running a rotary desk injection system, manufacturers can create a safer operating environment for operators, reduce the hazard of injuries and accidents, and ensure compliance with regulatory necessities. In addition, fostering a culture of safety awareness and duty amongst all employees is vital for maintaining a secure place of business.